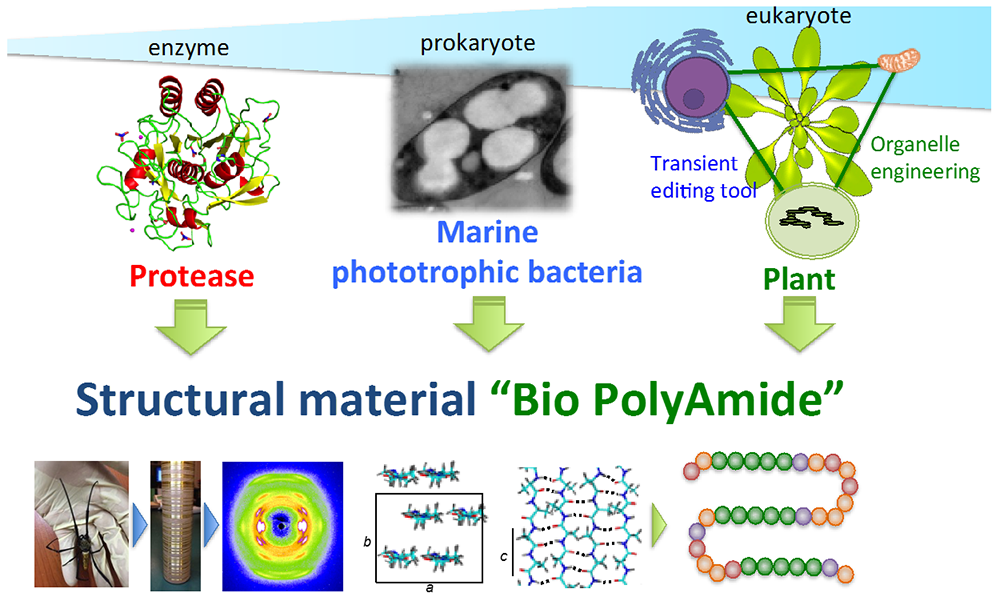

Our research group studies on design and synthesis of polypeptides for structural material engineering and plant engineering. Polypeptide has a huge potential to replace the existing materials and construct the biomass-based and sustainable society, because natural high-performance and functional materials are mainly composed of polypeptide. Polypeptide has been recognized as bioactive and functional material, however, use of those biopolymers as structural materials is still challenging. In my research, as a structural material, polypeptides are engineered as a structural material like spider dragline. Additionally, as a biomass-based composite material, plants including wood are modified using polypeptides as a gene/protein carrier in order to develop wooden bio-composite with high strength and excellent toughness. Here, summary of each research topic (Figure 1) is listed as follows:

1) New synthesis engineering of polypeptides

One of the major drawbacks of polypeptide and polypeptide-based materials is their limited synthesis methods. To synthesize polypeptide, the current synthesis techniques such as solid-phase peptide synthesis and recombinant DNA technique still have limitations in their productivity, atom economy and sequence regulations. The large-scale synthesis through an environmentally friendly process will be needed to establish polypeptide as bio-based materials. Our research group has successfully synthesized hydrophobic, amphiphilic, branched and cationic peptides via chemo-enzymatic polymerization, which provides a new insight for material design of polypeptide. Until now, mussel foot protein-like adhesive polypeptide, silk-like polypeptide, and thermally processable polypeptides were successfully synthesized by using protease as a catalyst. Furthermore, hybrid proteinase K, which is more stable and suitable for the chemoenzymatic polymerization, has been developed successfully.

To synthesize sequence-regulated polypeptides in large scale, we need to use ribosomes in vivo or in vitro. Synthesis of polypeptides needs nitrogen and carbon sources, which are essential biomass in various areas. Photosynthetic bacteria, especially, non-sulfur purple bacteria, fix nitrogen and carbon from atmosphere, and also produce efficiently biopolymers as an inclusion body. We developed a few strains of non-sulfur purple bacteria to produce biopolymers from nitrogen and carbon dioxide gases using photosynthesis.

2) Development of engineered polypeptides as structural materials

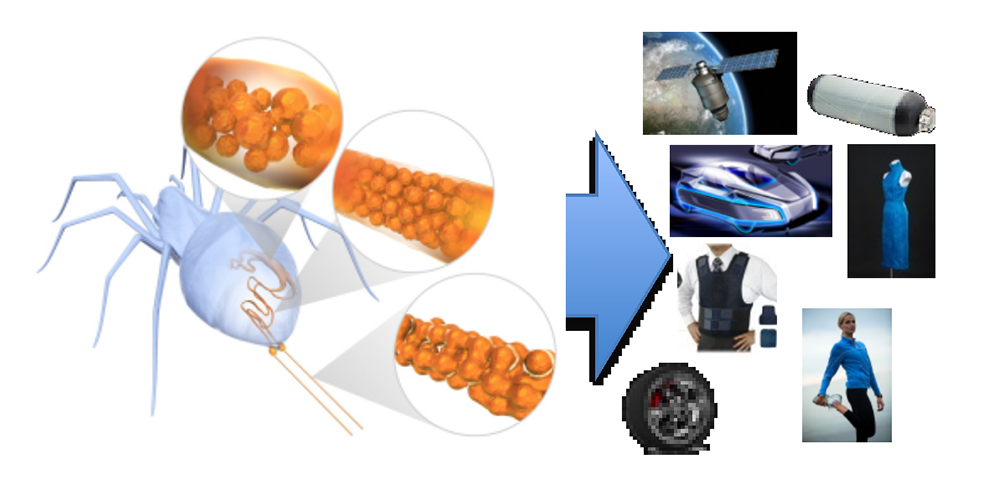

Use of polypeptide as a structural material is still limited and challenging, due to the lack of understanding on structure-function relationship, including roles of water molecules, of polypeptide-based materials. Spider dragline and web are composed of silk fibroins, which are typical structural proteins. The structural change during stretching deformation of silk fibers is an important factor to understand the different functions of different silk fibres. My research group has clarified the initial crystallization behaviour of silk molecules using SPring-8 X-ray analysis during the stretching of silk fibers. The structural analyses showed that the crystallization of silks following extension deformation is a critical determinant of their mechanical and optical properties in nature. Furthermore, my research group has clarified a mechanism of spinning of spider dragline silk, which will open a new door to produce structural protein materials via a water-based process (Figure 2). These findings will help guide the production of artificial silk fibres and facilitate the development of silk-inspired functional materials.

The industrial use of silk as a structural material has not been realized because of several technical issues. One of the issues is that its thermal processability and associated properties are not well understood. In particular, the effects of water content on thermal properties of silks are not studied enough to design silk material, which limit the material processing of silk and silk-like biopolymers. My research group cleared that the thermal/mechanical properties of silk materials are regulated by their water content and crystallinity. The new finding of the water-dependent thermal properties of silk is essential to producing bio-medical materials and bulk-scale structural materials with industrial applications, such as car frames, bulletproof jackets, and hydrogen storage tanks (Figure 2).

3) Bioengineered polypeptides for organelle engineering

Bioproduction using plants has been used or studied in a broad range of fields, such as drug discovery, energy production, food production, and material synthesis. Recently, the interest in bioproduction of bulk chemicals and polymers has increased owing to the rise of genome editing technology. However, in eukaryotes that have multiple organelles, it is difficult to create a metabolic pathway for bioproduction solely via modification of the nuclear genome. As proof, my research group modified the nuclear genome of a model plant (Arabidopsis thaliana) for the synthesis of polyhydroxyalkanoate, which is a typical bioplastic, but plant growth was inhibited due to the lack of mitochondrial metabolites. Thus, to produce a wide range of bulk chemicals and polymers using plants, it is necessary to modify the organelles in addition to the nuclear genome.

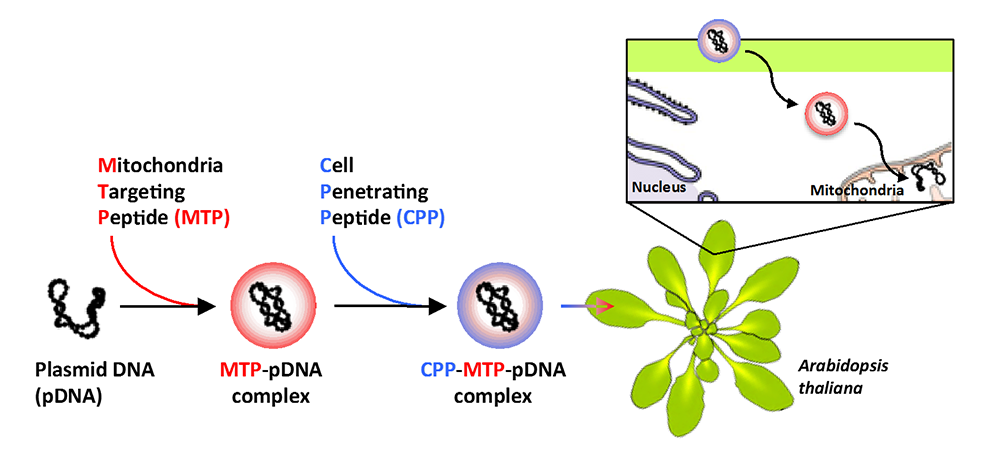

Polypeptides are versatile tools in biotechnology, especially in targeted delivery of bioactive molecules. Cationic sequences make efficient gene delivery agents due to membrane-destabilizing, DNA-condensing and pH buffering properties. A group of molecular transporters such as cell penetrating peptides (CPP) are short peptide sequences that vary significantly in sequence, hydrophobicity, polarity, and have the remarkable capacity for membrane translocation. Meanwhile, targeted delivery to essential organelles such as mitochondria and chloroplasts can be achieved with mitochondrial-targeting and chloroplast-transit peptides (MTP and CTP), which are typically N-terminal motifs predicted to form amphipathic helixes and enriched in positively charged basic residues. The combination of cationic, cell-penetrating and targeting signal components is an exciting new design parameter that enabled cellular uptake, localization and expression of exogenous DNA in the organelles of living plants (Figure 3). This new bioengineered polypeptide expands the potential of plant engineering to create plant-based tough and strong composite materials.